PHOTOGRAPHY JESPER GUDBERGSEN @yessirjesper and ZENIA JAEGER @makeupbyzeniajaeger

TEXT JESPER GUDBERGSEN @yessirjesper

In November of last year, we came up with the idea to make some tote bags for our submission family and a few fans. They’d have to be sustainably sourced, produced, manufactured. Here’s a tip, if you’re determined to do things with a sustainable, responsible, and all together mindful approach, it turns out to be a task that takes some time to figure out.

The actual bag itself is easy enough to find online for as low as 9 cents a pop, and finding a service that will print your logo is simple and about the same price. It’s all there at the click of a button, but it honestly feels too cheap to be entirely right. At a total cost of about $1 for the bag, logo, and shipping straight to your door, what’s really going on behind the scenes here?

Who has their hands on that bag as it’s being made, and what are their work conditions like? Does it ship from the other side of the world? What exactly is in that amazing-looking neon dye, how and where were the materials sourced?

Our submission tote bag started with an afternoon of volunteering at Fabscrap, an organization that collects and sorts leftover and deadstock materials and is open to the public. Founded in 2015, they receive about 3,000 – 5,000 pounds of fabric a week in materials that traditionally would have gone to landfills after being discarded by designers and clothing brands nationwide.

Their facility in the Brooklyn Navy Yard is open to the public, and you’re encouraged to volunteer your time sorting through the scraps. An afternoon at the facility is rewarded with five free yards of fabric. We were able to get a huge roll of unused and undyed deadstock cotton canvas and even found ribbing for the straps.

New York-based designer Luis Cascante lent his services by designing a tote bag with a gusseted bottom and longer handles, making the tote great for everyday use. The most sustainable bag is one that keeps being reused, so it was important to us to make a bag that is slightly larger than a flat-sewn standard tote, ultimately resulting in a versatile bag that’s suitable for groceries, toting your computer to work, or whatever you may need.

Each bag in this first limited run is sewn in Luis’ design studio in Queens, NY.

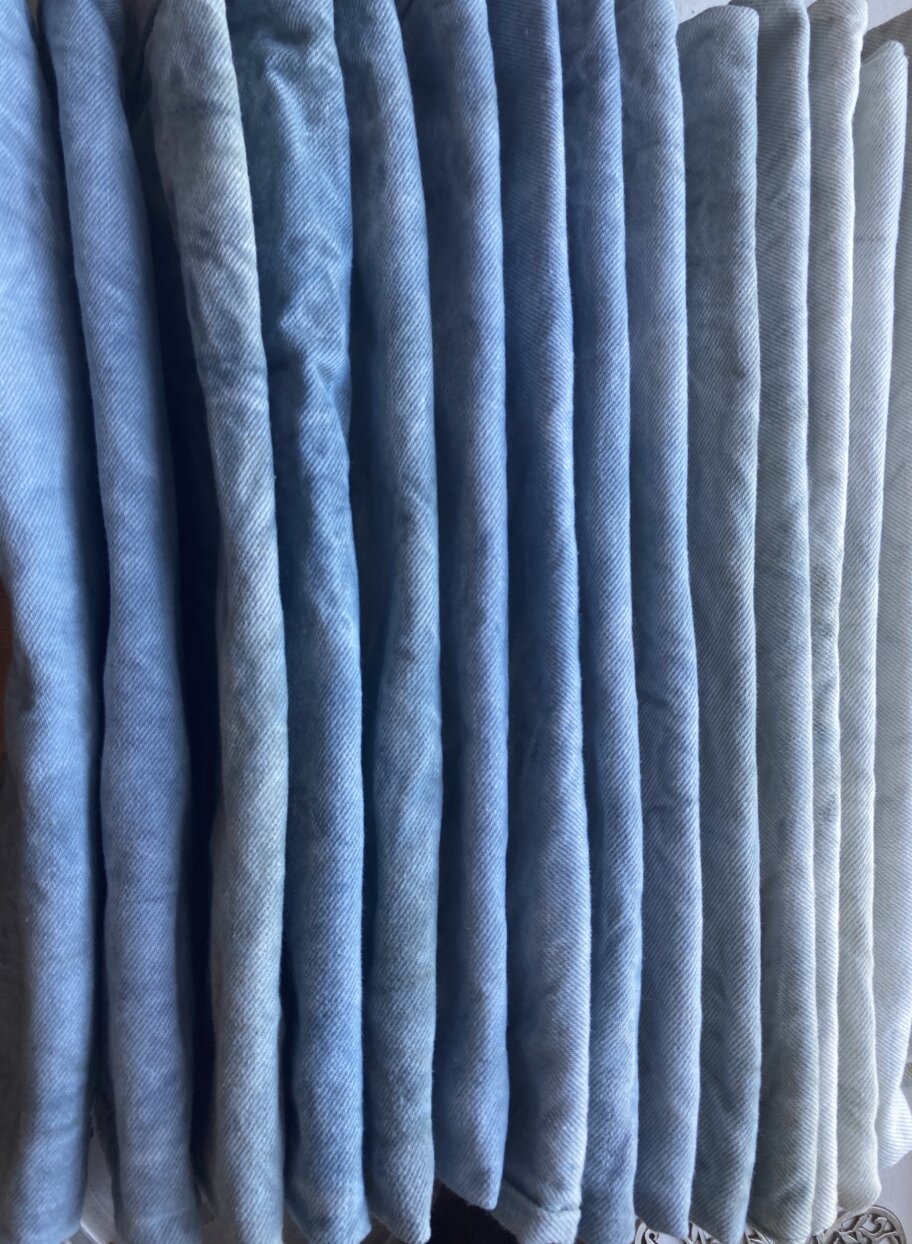

While we kept some of the bags natural and undyed color, we experimented with dyes on some of them. Natural indigo was our choice of dye, and we found a great supplier in Natural Botanicals who sells a 100% organic natural indigo (Indigofera tinctoria). This specific company only works with small producers on the growing and harvesting of their indigo.

This is also where we found the 100% organic natural Henna powder, which, when added to the indigo VAT, helps intensify the hue. Both of these natural dyes are Global Organic Textile Standard or GOTS certified.

We like that natural dyes have a certain level of unpredictability and variation – especially when used by inexperienced home DIYers such as ourselves. In our case, each bag turned out completely different from the next. Fun fact: one of our Submission editors hand-dyed each bag in their kitchen and is now slightly obsessed with dying everything in their house blue!

Once the bags were dry, one of our founders packed them up and brought them over from New York to our headquarters in LA, where submission family friend, Mali Koopman, was in charge of screen printing. Finding the right ink that cured nicely, sat neatly, and didn’t leach chemicals when washing down the sink was pretty tricky.

“I found it fascinating. The more I asked around to see what other companies used, who claimed to be completely sustainable and environmentally friendly, the more things became less transparent and almost secretive about what products were out there to run a sustainable print studio. However, the Submission brand was the only one to help me source the most eco-friendly inks. It’s not a surprise as the company is transparent and makes it easier for other people to be involved in making a difference.

The inks used for the Submission tote bags were by Permaset, which has also simplified my printing process. These inks wash out of my screens with just water; no solvents needed. After years of working with commercial inks for textile printing, this is rare. I work with mainly 230-305 mesh count screens, as my prints are mostly the size of my thumb and need the detail of a high mesh count. Because of this, I’m used to inks drying quickly in my screens, and removing the ink is even more difficult.

My usual solution would be considerable amounts of water, degraders, and haze removers to push out residue inks. Being able to cut this whole step has been excellent.”

Shop our submission tote bags here!

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |